So the machine came in on Wednesday. It’s an Indian grinder that came recommended from a few sites. Unpacking was an experience: Box to box to plastic to box to styrofoam. At least that way we’re sure it’s not damaged.

On the way through all the cardboard I was greeted with the name of the (I believe) import company:

Well… That’s a good omen.

My first test was with rice and water. I read that sometimes it’s good to do a dry run with disposable material so that you take out any oils, residue, etc… from the manufacturing process.

Next, I tried to salvage the work that I did the last time. I pulled the salvaged material from the refrigerator, and put it in the machine. It turns out, as I later found out, this was a pretty big mistake. It makes sense when you come to think of it. The nibs are loaded with oil (the cacao butter part), so having them refrigerated does the same thing as it does to butter (hardens it). So technically I should’ve let it thaw a bit more first (or as I read later, put it in the over at 150º F).

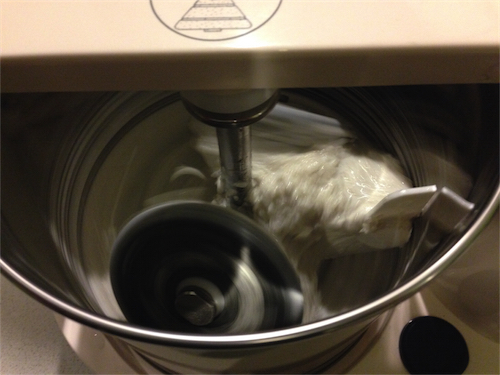

So, none the wiser, I proceeded with trying to grind the cacao.:

Surprising it worked pretty well at first as it ground the nibs into a power. However, the grinding caused the cacao mass to start to form a cake on the bottom of the grinder. Ultimate, this put too much force upwards on the stones and the machine’s failsafe kicked in. I tried it a second time, and got the same result.

So back to the internet I went (BTW, it must be said that most sites out there are ridiculously poorly written – more on that later). A couple of suggestions that made sense:

- Use a hair dryer or heat gun to heat the grinder

- Use an oven to heat at low temperature (150º F) the cacao material to help the cacao butter melt.

#1 didn’t make too much sense to me as one of the issues you have to be thoughtful about is the fact that the machine may overheat. So applying direct heat to the general “machine area” seems to only accelerate this. So I proceeded with #2.

20 minutes in the oven, and the material started to look good (I didn’t get a snapshot, but it started to look like the liquor that I saw with the juicer). So I put it in the machine again, and quickly it started to dry out and cake again (oh no!). So this is the crux of the issue… how do you get a liquid when you have solids to start and heat and pressure are the only thing that will help, but heat will also damage the equipment… It’s a fine balance.

So I decide to move forward and add the cacao butter to the power. First I had to figure out the proportions I wanted to use. I decided to go with a more milky chocolate, and used the following proportions:

- Cacao Liquor (which includes some butter): 30% (really about 15% if you account for the butter)

- Cacao Butter: 10% (really a total of 25% if you add the above)

- Sugar: 30%

- Nonfat Milk Powder: 30%

- Lecithin: 0.5%

- Vanilla: 2 teaspoons

Note: the total is greater than 100% (100.5%), but you should know that proportions are approximate as you ultimate end up measuring in grams. So 30% could be 29.5% or 30.5%.

Once I had my proportions together, I first melted the cacao mess and butter:

I proceeded with the melted cacao mess and butter in the machine, followed by adding the powdered mix (the rest). Obviously the volume started to grow as I essentially tripled (see proportions above) what I had. I put a little in at a time, and the cacao simply couldn’t stay liquid. It’s as though there were too many dry solids sucking up all the oil available.

Here’s a candid snapshot that Monet got of me: Not sure if I look frustrated or what.

So after a couple of hours of trying this — go back to the oven to melt and again try to grind — I gave up. The material was just too dry, and it took longer and longer to melt in the oven. I did taste it along the way, and noticed that it did taste quite good (yum!)

So after a couple of hours…

… we had hot chocolate!

Very creamy, but a lot of solid still in it. It will be very tasty to have today (Saturday) on this first snowy day in Boston.

So what’s the lesson here? I think there are a few:

- There is very fine balance/chemistry at play here that I have to master.

- Heat is both a friend and enemy.

- I have to get more comfortable with spinning and whirling machinery… it’s not all going to explode in my face.

For the next try, I think I’ll go back to the Breville, and use a heat gun to try to help the nibs melt. I think I have a good idea, but need a “third hand”, but not the kind that you use for electronics.

See you soon!